Factors Affecting Carbon Black Dispersion

Oct 20, 2021

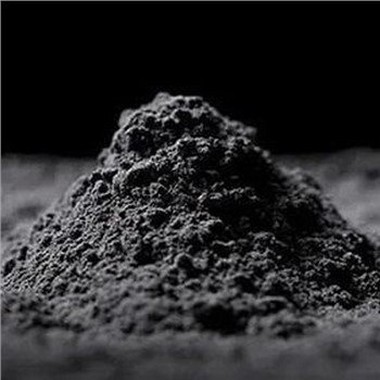

The dispersion process of pigment carbon black is mainly affected by three factors:

1. The essential characteristics of carbon black: the original particle size, structure and surface groups of carbon black will have a great influence on dispersion. Normally, carbon black has a small original particle size, low structure, and low volatile content. It is difficult to disperse, otherwise it is relatively easy.

The darker the carbon black, the higher its acidity, with a pH between 2.5 and 4.5, and the higher the adsorption capacity. The pH of ordinary carbon black is almost neutral, so its adsorption capacity is not obvious. Because the adsorption capacity of carbon black has a special effect on the drying properties of the coating, the drying rate of the coating film is often reduced due to the adsorption of the drier in the paint. When the PH value of carbon black is below 4, the greater the acidity, the greater the adsorption capacity of the drier, and the more obvious the impact on the anti-drying performance. Therefore, when designing the paint formula, consider increasing the amount of drier appropriately.

2. User's formula: The carbon black user's formula, base material, solvent and resin properties will significantly affect the final dispersion of carbon black, especially the choice of carbon black resin.

During the application process, the pigment must be dispersed to the state of fine particles that meet the optical properties. Carbon black is one of the most difficult to disperse among all pigments. Therefore, the dispersion of carbon black will directly affect the blackness and hue of carbon black. And covering ability, directly affect the user's final use effect.

3. Carbon black dispersing equipment: the dispersing effect of different dispersing equipment under the same conditions is quite different. Choosing the right dispersing equipment is what engineers must pay attention to.

Before dispersing, choose a suitable wetting agent. It is best to fully moisten the pigment carbon black. After a suitable time of wetting, it is best not to be too fast in the initial grinding stage, otherwise the new interface of the pigment carbon black will not be wet in time, which will cause Dispersion is difficult and thickening occurs. The grinding speed must be controlled to reduce the thickening phenomenon. During this period, there is also a certain relationship with the operator's dispersion equipment and dispersion process. When the pigment carbon black aggregates are slowly opened, their specific surface area will increase accordingly. The specific surface area increases faster than the rate of being wetted, and the viscosity will increase rapidly. Until all the new pigment surface is wetted, the viscosity will be relatively stable. The blackness of pigmented carbon black is the most important technical indicator. The smaller the particle size, the lower the structure of carbon black and the more difficult it is to disperse. Therefore, when the cost is acceptable, the dispersion performance should be selected as much as possible. A good dispersant and wetting agent, using a high-speed sand mill with excellent performance, through good operation, fully disperse the pigment carbon black.